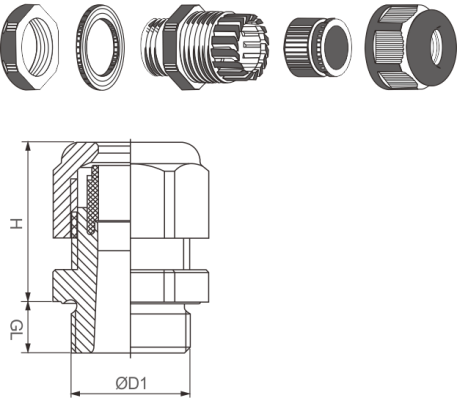

PG/M/MG type nylon cable gland

Product parameter

|

Item No. |

Thread |

(mm) |

H (mm) |

GL (mm) |

(mm) |

|

JX-7 |

PG 7 |

3-6.5 |

21 |

8 |

15 |

|

JX-7 |

PG 7 |

2-5 |

21 |

8 |

15 |

|

JX-9 |

PG 9 |

4-8 |

21 |

8 |

19 |

|

JX-9 |

PG 9 |

2-6 |

22 |

8 |

19 |

|

JX-11 |

PG 11 |

5-10 |

25 |

8 |

22 |

|

JX-11 |

PG 11 |

3-7 |

25 |

8 |

22 |

|

JX-13.5 |

PG 13,5 |

6-12 |

27 |

9 |

24 |

|

JX-13.5 |

PG 13,5 |

5-9 |

27 |

9 |

24 |

|

JX-16 |

PG 16 |

10-14 |

28 |

10 |

27 |

|

JX-16 |

PG 16 |

7-12 |

28 |

10 |

27 |

|

JX-21 |

PG 21 |

13-18 |

31 |

11 |

33 |

|

JX-21 |

PG 21 |

9-16 |

31 |

11 |

33 |

|

JX-29 |

PG 29 |

18-25 |

39 |

11 |

42 |

|

JX-29 |

PG 29 |

13-20 |

39 |

11 |

42 |

|

JX-36 |

PG 36 |

22-32 |

48 |

13 |

53 |

|

JX-36 |

PG 36 |

20-26 |

48 |

13 |

53 |

|

JX-42 |

PG 42 |

32-38 |

49 |

13 |

60 |

|

JX-42 |

PG 42 |

25-31 |

49 |

13 |

60 |

|

JX-48 |

PG 48 |

37-44 |

49 |

14 |

65 |

|

JX-48 |

PG 48 |

29-35 |

49 |

14 |

65 |

The terminal connector acts as a bridge between the electronic parts. Its main function is conduction and minimum contact impedance. Therefore, there are some specifications for the main parameters of the terminal connector product. 1. The insertion force and pull-out force of a terminal connector generally refer to the coordination of a single terminal, and the connector requires a minimum insertion force and a maximum pull-out force. 2. The combination and pull-out force of the terminal connector refers to the overall matching insertion force and pull-out force of the connector. 3. The retention force of the terminal connector refers to the axial force that the terminal can withstand after mating with the HSG. The retention force is sufficient to prevent the terminal from exiting the plastic body (pin removal) or poor contact. 4. The positive force of the terminal connector is the normal force of the terminal perpendicular to the contact surface of the terminal after the connector is inserted. The positive force guarantees the reliability of the contact between the terminal male and the female, which is an important parameter considered for terminal design and material selection. . The holding force of a terminal connector refers to the vertical and horizontal pulling force that the terminal of the connector can withstand. This test is usually done according to customer requirements. Precautions for the use of terminal connectors:

1. The purpose of producing "terminal connectors" is to connect electricity and electrical signals, so please do not use them for components or parts of components that are premised on applying mechanical force to the combination of "terminal connectors".

2. "Terminal connectors" are divided into two types for wiring in equipment and wiring between equipment. "Terminal connectors" for wiring in equipment can only be used for the "inside of the main body of the equipment" specified by the Electrical Appliances Safety Law. Wiring", please perform proper treatment on the equipment side to prevent ordinary people from touching it.

3. Please use the product within the range of the rated value and performance specified in the product specification when using it. In addition, the rated value and performance specification are specified as parts. In actual use, please confirm that it complies with the regulations and design related to the equipment used. Standards, etc.

4. Do not place the "terminal connector" and process products or processed products in an environment with corrosive substances, corrosive gases, high temperature and humidity, and direct sunlight, otherwise the terminals will be corroded or the insulation performance of the plastic case will be aging, etc. This may result in malfunction of the equipment, etc.

5. Do not apply external force to the terminal connector and the work-in-process or processed products (wiring harness, etc.), otherwise it will cause deformation and damage, resulting in poor connector performance.